Significant Features of a Frequency Inverter

Frequency inverters are devices capable of converting AC frequency to DC frequency. It can be well defined as a device used to convert direct current (DC) to alternating current (AC). It is a type of current provided by utility providers. A three-phase motor is powered by “retargeted” voltage. Therefore, it is indispensable for the productivity and durability of an electric drive. Improving its usability value depends on the type of device you are using. At the same time, its price is taken into account. These inverters are mostly found in homes and buildings that are fully or partially dependent on a DC power source. DC power sources include low-power DC power, wind power, and hydroelectric power.

Main characteristics of a variable frequency drive:

A series of independently developed variable frequency drives are available to meet requirements. They have high reliability and are multifunctional for electric motor drives.

These are integrated with many advanced control technologies; Voice frequency, simple PLC operation, key/auxiliary frequency reference, motor noise regulation and process PID control.

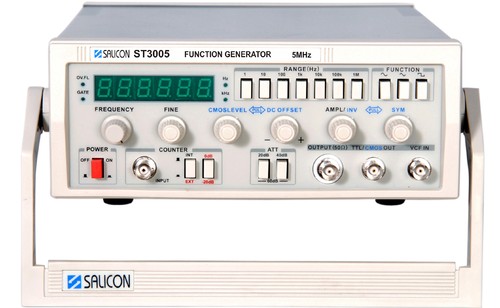

In addition to these features Frequency generator, the inverters are equipped with a number of safety features such as protection against short circuits, ground faults and overvoltages and under voltages.

The alternating current generated by this device can be adjusted in amplitude and frequency.

Different types of frequency converters are available, depending on the area of application. Its quality depends on many criteria such as energy efficiency, energy efficiency, internal protection and power quality.

With the help of these inverters, all these motors can maintain strong alternation of speed and torque without any damage.

Its safety features include “PID feedback anomaly” and “overvoltage stall”, which protects the motor even in harsh operating environments.

It was used to control the rotational speed of an alternating current (AC) electric motor.

With their extensive services and numerous functions, they can meet all the requirements of modern industrial applications. With these inverters it is possible to achieve a uniform and consistent standard of transmission. It is equipped with automation and self-regulating ramps; In this way, the starting procedure is very simple. All functions are easily operated by their default settings, and its installation is very flexible. To do this, just press the “Start” button. In addition, all these inverters are equipped with digital and analog inputs and outputs and have an optional RS485 interface. Other features of these inverters include four-quadrant drive, freely programmable encoderless field-oriented control, linear V/f behavior and sensorless vector control.