Micro Machining Services: Revolutionizing Precision Manufacturing

Introduction

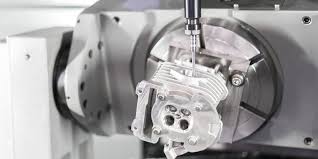

Micro machining services represent a cutting-edge approach in the field of precision manufacturing, characterized by their ability to produce components with unparalleled accuracy at the micrometer scale. As industries continue to demand smaller, more intricate components, micro machining has emerged as a critical Micro milling machine CNC technology for achieving high levels of precision. This comprehensive article explores the various facets of micro machining services, including their principles, techniques, applications, advantages, challenges, and future trends.

What are Micro Machining Services?

Micro machining services involve the use of advanced manufacturing techniques to create tiny components with exceptionally high precision. These services encompass a range of operations, including micro milling, micro drilling, micro turning, and micro EDM (Electrical Discharge Machining). The primary goal of micro machining is to achieve intricate and detailed features on small workpieces, often with tolerances in the micrometer range.

Key Characteristics of Micro Machining Services

- High Precision

- Micro machining services are designed to achieve extremely tight tolerances and high accuracy. The precision of these services is critical for producing components with fine details and complex geometries.

- Advanced Equipment

- Micro machining utilizes specialized equipment, including micro mills, micro lathes, and micro EDM machines. These tools are engineered to handle small-scale operations with high precision.

- Sophisticated Control Systems

- Computer Numerical Control (CNC) technology is integral to micro machining services. CNC systems enable precise control of machine movements and operations, ensuring consistency and repeatability.

- Material Versatility

- Micro machining services can process a wide variety of materials, including metals, plastics, ceramics, and composites. The choice of material depends on the specific requirements of the application.

Techniques in Micro Machining

Micro machining encompasses several techniques, each tailored to specific manufacturing needs. Understanding these techniques is essential for selecting the appropriate method for different applications.

1. Micro Milling

- Description: Micro milling involves using small-diameter end mills to cut intricate features into a workpiece. This technique is ideal for creating detailed patterns, slots, and complex shapes.

- Applications: Commonly used in the production of small components for electronics, medical devices, and aerospace applications.

2. Micro Drilling

- Description: Micro drilling creates tiny holes with high precision. This technique is essential for applications that require exact hole placement and size.

- Applications: Frequently used in electronics for creating vias in circuit boards and in medical devices for precision openings.

3. Micro Turning

- Description: Micro turning involves using small lathes to machine cylindrical parts with high precision. This technique is used to produce miniature shafts, pins, and other rotational components.

- Applications: Applied in manufacturing small components for automotive, aerospace, and medical industries.

4. Micro Electrical Discharge Machining (EDM)

- Description: Micro EDM uses electrical discharges to erode material from a workpiece. This technique is ideal for creating complex shapes and fine details on hard materials.

- Applications: Utilized in the production of intricate molds, dies, and high-precision components.

5. Micro Grinding

- Description: Micro grinding involves using small grinding wheels to achieve precise surface finishes and geometries. This technique is suitable for finishing operations and achieving tight tolerances.

- Applications: Used in producing high-quality surfaces and fine details on various materials.

Applications of Micro Machining Services

Micro machining services have a broad range of applications across various industries, where precision and miniaturization are critical. The following sections explore some of the key areas where micro machining is making a significant impact.

1. Electronics Industry

- Microelectronics: Micro machining is essential for manufacturing microchips, circuit boards, and connectors. The ability to create detailed and miniature electronic components is crucial for the advancement of electronic devices.

- MEMS Devices: Micro Electromechanical Systems (MEMS) are critical for sensors, actuators, and micro-scale systems. Micro machining enables the fabrication of these devices with high precision.

2. Medical Industry

- Medical Devices: The production of medical implants, surgical instruments, and diagnostic equipment relies on micro machining for precision and complexity. Components must meet stringent requirements for accuracy and biocompatibility.

- Prosthetics and Implants: Micro machining allows for the creation of custom prosthetics and implants that fit precisely and function effectively within the human body.

3. Aerospace Industry

- Aerospace Components: Micro machining technology is used to produce lightweight, high-precision components for aerospace applications, including sensors, connectors, and structural parts. Precision is vital for the performance and safety of aerospace systems.

- Space Exploration: Micro machining plays a role in the development of components for space exploration, such as miniature sensors and instruments used in space missions.

4. Automotive Industry

- Automotive Parts: Micro machining enables the production of small components for automotive systems, such as fuel injectors, sensors, and precision gears. These parts contribute to the efficiency and reliability of automotive systems.

- Customization: The ability to produce custom parts and components allows for tailored solutions and innovations in automotive design.

5. Consumer Goods

- Micro-Devices: Micro machining is used to manufacture small components for consumer products, including watches, optical devices, and compact electronic gadgets. The technology enhances product design and functionality.

- Customization and Personalization: Micro machining allows for the creation of customized parts and features, providing unique design options for consumer products.

Conclusion

Micro machining services have revolutionized precision manufacturing by enabling the production of intricate and high-quality components at the micrometer scale. With its diverse techniques, wide range of applications, and numerous benefits, micro machining technology is a crucial tool in various high-tech industries. As the field continues to advance, manufacturers can leverage micro machining services to achieve new levels of precision, efficiency, and innovation. The ongoing developments in technology and materials promise exciting opportunities for the future of micro machining, making it an essential area of focus for precision engineering and advanced manufacturing.